Simplify Your Label Software

Are you managing many label files?

One of the strengths of enterprise label software is that it can connect label files to data sources and then use business logic to print the right variable data on the right label at the right time. However, many businesses aren’t harnessing the power of modern label software that could potentially save thousands of hours of labour plus almost completely eliminate labelling errors.

BAD PRACTICE: MANUAL DATA ENTRY

Many organisations use only the design component of their labelling software, so when they need to create a new label, they open an existing label file, substitute the appropriate data, and then either print or save the result as a new label file.

This leads to exponential growth in data storage, along with associated costs and security problems. For companies that create a different label for each SKU, shelf tag or shipping address, the result is an ever-growing — and ultimately unmanageable — library of thousands of static label designs and formats.

This approach also builds complexities and waste into the system by needlessly duplicating data, making it impossible to implement a single-source-of-truth data strategy. When data changes, every individual label that includes that data has to be located, opened, updated and saved.

GOOD PRACTICE: CONNECT TO DATA SOURCES

Rather than storing static data in each label file and managing one label format for each SKU, shipping address or production date, design each of your labels with variable data fields that link to your existing sources. The data can come from virtually any data source — ERP systems (such as SAP or Oracle), local spreadsheets and text files, system calendars or clocks, image databases or even weighing scales. The enterprise label software will automatically insert the correct information into the label fields at print time based on your own business rules.

BETTER PRACTICE: USE LAYERS AND CONDITIONAL PRINTING

If your enterprise labelling software includes layers, you can use them to hold different kinds of information and variable data, and then hide or display each layer based on user-defined conditions when a label is printed. By using design layers and conditional printing of data thoughtfully, you can dramatically reduce the number of label files you need to create and manage.

For example, a chemical manufacturer needs its hazard labelling to comply with the regulations of eight different countries. Instead of building and maintaining eight individual label formats, they built a single format in which each country’s data fields and layout were stored on a separate layer. At print time, a rule in the label populated the fields on the appropriate layer and printed only that layer.

Use conditional printing to create multiple labels from a single label design, and reduce the number of labels you need, enabling a lean, secure, economical system.

BEST PRACTISE: ERP INTEGRATION AND DATA MANAGEMENT

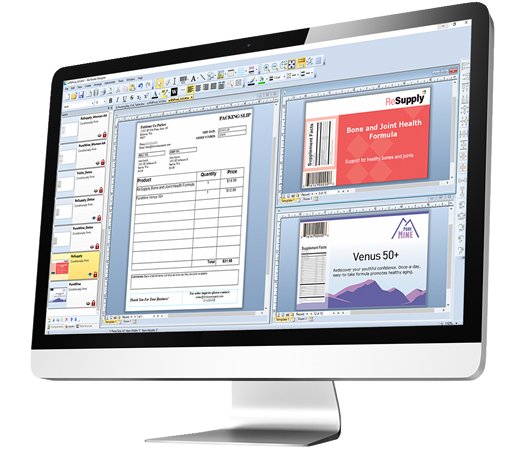

BarTender’s seamless integration with ERP systems enables automation at the enterprise level, providing support for mission-critical processes, increasing labelling accuracy and improving efficiencies throughout the supply chain.

Essentially, label data, formats and print triggers are all automatically managed by your existing production systems, effectively eliminating manual handling and errors.

BarTender’s native integration platform, Integration Builder, makes it easy to create integration files from scratch, no coding required. Capabilities include:

- Initiating printing automatically at “trigger” events, such as the arrival of an e-mail, a saved file, or a modified database

- Connecting to and communicating with clients via TCP/IP, UDP or HTTP

- Performing basic file operations, such as move, rename, delete or copy

- Integrating with ERP systems with support for direct connectivity.

BarTender label creation software enables organizations around the world to improve safety, security, efficiency, and compliance.

Not using BarTender? Get in touch with us so we can get you started with powerful automation and enterprise label software.

Already using Bartender? We might be able to automate your labels even more. Ask us for a free consultation today