Embracing Lean Thinking: The Five Principles for Success

In today’s dynamic and competitive business landscape, organisations strive to optimise their processes, enhance customer satisfaction, and maximise efficiency. Lean thinking, derived from the Toyota Production System, offers a proven methodology to achieve these goals. At its core, Lean thinking emphasises creating value for customers while minimising waste and continuously improving operations. In this blog post, we will explore the five core principles of Lean thinking and their significance in driving success and fostering a culture of continuous improvement.

Principle 1: Identify Value from the Customer’s Perspective

The foundation of Lean thinking lies in understanding and fulfilling customer needs. To implement this principle effectively, organisations must engage with customers actively, gather feedback, and study preferences to identify what genuinely matters to them. By distinguishing value-adding activities from waste, companies can optimise their processes to focus on what customers truly value. This customer-centric approach enables organisations to tailor products and services to meet specific demands, ultimately leading to improved customer satisfaction and loyalty.

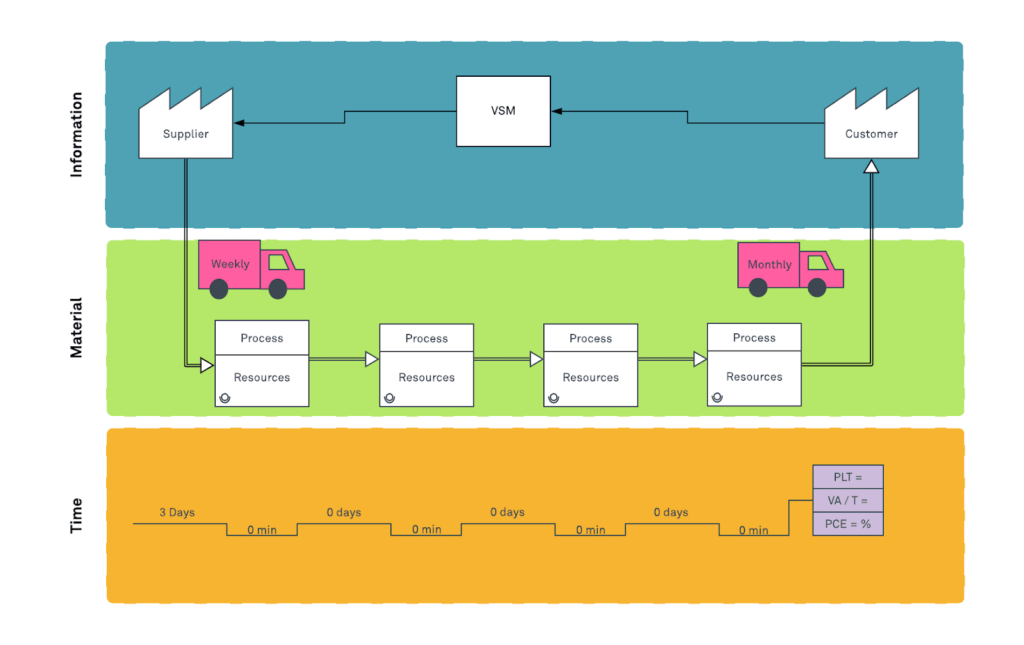

Principle 2: Map the Value Stream and Eliminate Waste

After identifying customer value, the next step is to analyse and optimise the processes involved in delivering that value. Value stream mapping provides a comprehensive view of the entire process, helping organisations identify inefficiencies and waste. By systematically eliminating waste, such as overproduction and unnecessary transportation, organisations can achieve higher levels of efficiency, reduced lead times, and increased productivity.

Principle 3: Create Flow Through the Value Stream

Creating a smooth and continuous flow of work and information through the value stream is critical for Lean success. By designing processes to minimise disruptions and resequencing tasks, organisations can reduce waiting times and improve responsiveness to customer demand. Smaller batch sizes and the implementation of pull systems further contribute to efficient flow and agility within the organisation.

Principle 4: Establish Pull (Produce Only What is Needed)

Lean thinking promotes a pull system, where production or work initiation is triggered by actual customer demand. This approach avoids overproduction, excess inventory, and resource wastage. By aligning production with customer demand and adopting a just-in-time approach, organisations can optimise their processes, respond effectively to changing demands, and enhance overall efficiency.

Principle 5: Strive for Perfection (Continuous Improvement)

Continuous improvement, or Kaizen, is the heart of Lean thinking. Rather than seeking absolute flawlessness, organisations should focus on making small, incremental improvements regularly. This approach encourages a problem-solving mindset at all levels of the organisation, driving sustained growth and adaptation to market changes. Embracing a culture of continuous improvement fosters innovation and empowers employees to contribute ideas and take ownership of their work.

Lean thinking offers a powerful set of principles for organisations to optimise their operations, provide exceptional value to customers, and remain competitive in today’s fast-paced business environment. By identifying customer value, eliminating waste, creating flow, establishing pull, and striving for continuous improvement, organisations can embark on a journey towards Lean excellence. Embracing these principles as part of the organisational culture enables continuous growth, innovation, and a customer-centric approach that is key to success in the modern business world.