Printing with Zero Waste

If you’re familiar with label printing, you’ll be aware of the potential frustrations, waste and headaches that label liners can bring. The liner, which is 50% of the label, immediately becomes waste material upon application. In a business environment where efficiency is everything and environmental regulations are increasing, it just doesn’t make sense.

That’s why linerless labelling is gaining traction around the world and is expected to grow 30% in the next five years. So what are the benefits and what changes do you need to make to get on board?

What are Linerless Labels?

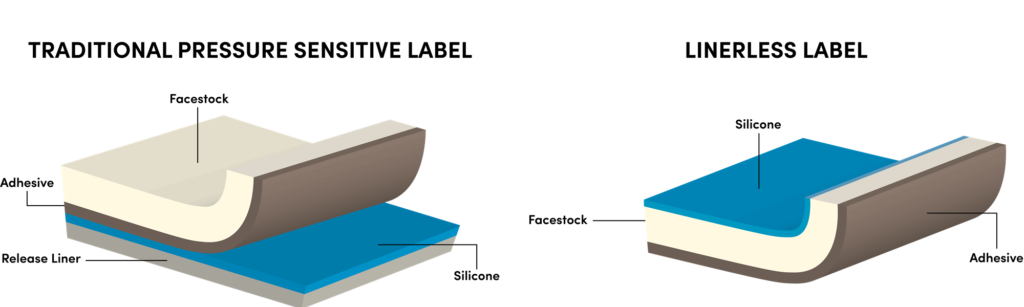

Linerless labels are adhesive labels that do not have the typical liner or backing material found in conventional label rolls. Unlike standard labels, which require the liner to separate the adhesive from labels underneath on the roll, linerless labels feature a silicone release coating on the top layer of the labels and a special adhesive that enables them to peel away from labels underneath, similar to a roll of tape. These labels offer a more environmentally friendly and efficient solution for product labelling and packaging.

Benefits of Linerless Printing

The adoption of linerless labelling brings many advantages for businesses:

Environmental Impact: Obviously, one of the most significant benefits of linerless labelling is its positive impact on the environment. Each year, millions of tons of label liner waste are sent to landfills and incinerators. Standard liners are not recyclable in kerbside recycle bins. Specialised recycling programs can help to reduce label waste. But the best solution — for our industry and for the planet — is to eliminate liners altogether.

Enhanced Productivity: Linerless label rolls contain approximately 50% more labels than traditional label rolls with a liner, leading to fewer media changes and uninterrupted production. This reduction in downtime boosts overall productivity and optimizes the labelling process.

Compliance with Environmental Directives: As regulations related to waste reduction and recycling become stricter, businesses are compelled to seek environmentally friendly alternatives. Linerless labels offer a compliant solution to meet these stringent environmental directives.

Workplace Safety: The absence of liner piles that typically accumulate beneath printers eliminates workplace slip hazards, promoting a safer work environment.

Reduced Weight and Shipping Costs: Linerless label rolls weigh up to 40% less than traditional labels with a liner. This weight reduction not only makes mobile printers more manageable but also reduces shipping costs.

Flexibility in Label Lengths: Linerless labels offer the flexibility to print varying label lengths, because the label size is cut at time of print. This provides versatility in meeting different product labelling requirements and can also reduce waste from unprinted sections of the label.

Key Points to Consider When Switching to a Linerless Printing Solution

To ensure a successful linerless labelling implementation, businesses should consider the following:

Print Performance: Select a linerless printing solution that offers high-quality and durable prints, ensuring optimal readability and longevity of labels. Special platen rollers and cutters are required in linerless printers to handle the absence of a liner.

High-Quality Labels: Linerless labels must be carefully manufactured and wound on the core to ensure a proper fit in the printer and prevent feeding issues or jamming. Choose a reputable manufacturer that adheres to strict quality standards to ensure precision in the manufacturing and winding of linerless labels.

Compatibility Testing: Extended print quality testing is essential to prevent adhesive buildup on the printhead and platen roller. Rigorously test the linerless labels with the compatible printers to ensure minimal adhesive buildup, smooth label throughput, and reduced maintenance requirements.

Linerless labelling is a game-changer in the label industry, offering a sustainable and efficient solution that aligns with modern business requirements.

PrintDATA will support all of our customers and end users to make the switch over time to more efficient, less wasteful linerless labels. We’re excited about these new sustainable developments and are always here to help. We partner with leading printer manufacturers offering linerless hardware, such as Zebra, Honeywell and TSC. We also offer high-quality linerless label material in custom sizes, along with the expertise required to pair them with the right printer.

By selecting PrintDATA as your linerless printing partner, you can unlock the full potential of zero-waste labelling, paving the way for a greener and more streamlined future.