Keeping Up with Woolworths: Implementing 2D Barcodes

Woolworths, one of Australia’s largest retail chains, is transitioning its product identification and labelling to 2DBarcodes by GS1. The move is aimed at improving the efficiency of point-of-sale operations, particularly in the fresh food categories, starting with meat and poultry.

The following guide provides step-by-step instructions to help suppliers with this transition.

STEP 1: Find your GTIN

If your product is variable weight, you will need to consider the branding of your products. For supplier-branded products, you will allocate your own GTINs for each of your products. For Woolworths-branded products, Woolworths will provide you with GTINs for each of your products.

For fixed-weight products, you will need to contact GS1 Australia for assistance in implementing 2DBarcodes with Woolworths. Once you have created your GTINs, you will need to send them to Woolworths for entry into their Point-of-Sale (POS) system.

STEP 2: Design and check your barcodes

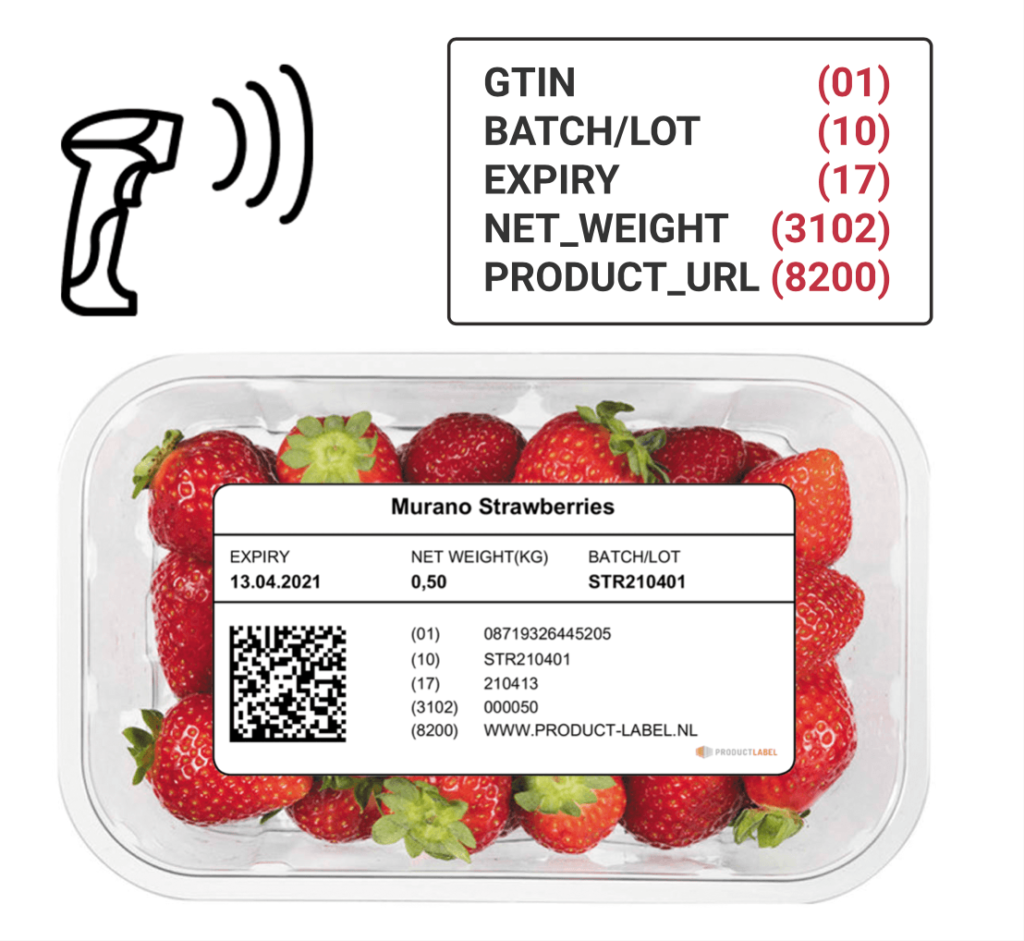

Woolworths is using the GS1 DataMatrix barcode symbol for their transition to 2DBarcodes. The GS1 DataMatrix is a 2D barcode symbol made up of individual dots or squares. To ensure your 2DBarcodes scan first time, every time at the Woolworths checkout, it’s important to submit your label samples to GS1 Barcode Check. This service offered by GS1 Australia tests a range of factors, including compliance to global standards, size, colour, print quality, numbering, and more. Once tested, GS1 will provide you with a Barcode Verification Report indicating the compliance of your barcode and any changes you may need to make. This report is required by Woolworths to check that the correct AI’s and data have been encoded in each 2DBarcode.

STEP 3: Contact your print partners

It is recommended that suppliers use scanning, printing, and labelling supply partners that are familiar with 2D barcodes and GS1. Getting them involved early in the process is crucial to avoid any complications with product labels.

Some of the measures these partners will implement are:

- a barcode quality plan as a Standard Operating Procedure (SOP) within your business

- A scheduled printer clean and service on a scheduled basis to maintain the barcode print quality.

- Introducing a printer with an in-built scan test to ensure readability.

- Introducing 300dpi printers which offer higher resolution print, perfect for 2D barcodes.

- Ensure your 2D codes adhere to the recommended barcode symbol size.

“We’re pleased that so many of our suppliers can see the benefits of transitioning to 2DBarcodes,” says Jennifer Keegan, Head of Support Portfolio Delivery, Woolworths Group. “It’s important for suppliers that are transitioning to 2DBarcodes to get in touch with their print partners early on in the process. This will help to smooth the transition and get the right quality product labels in-store.”

PrintDATA has over 25 years’ experience in barcoding and labelling. We supply the full solution with everything you need for the transition: printers, labellers, software, labels, and most importantly, expertise.

If you supply products to Woolworths and are yet to transition to 2DBarcodes, it’s time to get started. Start with this guide prepared by GS1 and Woolworths to ensure a smooth transition and improved efficiency at the point of sale.

Then get in touch with PrintDATA to ensure your transition maintains full compliance and efficiencies.