5 Reasons to Try Thermal Inkjet Printing

If you are sick of inkjet printers being too expensive, too complicated, and requiring too much maintenance, you need to try the Domino G50i. It is our entry-level thermal inkjet (TIJ) coder which is ideally suited to code text, logos, barcodes, and variable data onto your primary and secondary packaging. It has been designed to be easily self-installed, direct from the box, without any technical knowledge required. Here are 5 reasons you’ll like the G50i.

1. Clear codes that go the distance

The G50i produces clear, high-contrast codes. Operating at speeds of up to 220m/min, you can expect rub-, smudge- and scratch-resistant codes that withstand handling, transport and post-print processes. Adjustable DPI settings and ink saving options give you the flexibility to adjust code quality and increase prints per cartridge.

2. Flexible code formats

The G50i is ideal not only for batch and date coding but also for complex code formats, item-level serialisation, 2D barcodes, check weighing and track and trace coding. The high resolution lets you print readable barcodes, logos and graphics. The label formats are flexible, giving you the option to print combinations of barcodes, logos, and variable data on one message.

3. Easy to integrate

The G50i printer has a remarkably small footprint, ideal for tight production environments. It also comes with basic mounting brackets, making installation quick and easy. It can be purchased with optional plug-and-play accessories, like a 3-colour beacon, line speed encoder, and external sensor.

The printhead can be mounted vertically or horizontally, meaning you can print on the top or side of your cartons. This gives you heaps of flexibility when installing it on your production line.

4. Easy to use

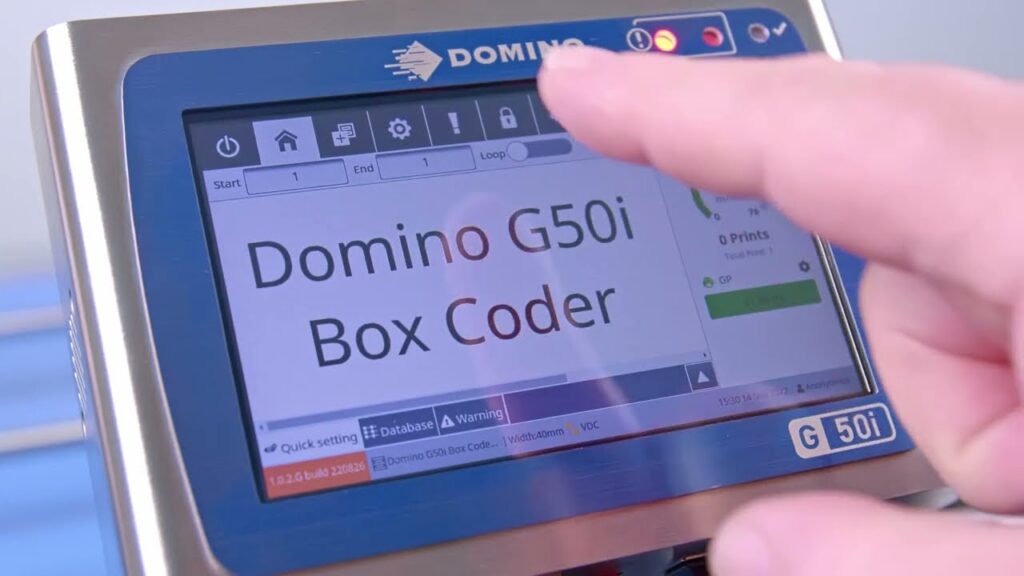

With a modern user interface displayed on a 5-inch full colour touchscreen, using the G50i is as simple as using a tablet. The interface includes a label editor, meaning you can easily create and edit your messages right on the controller. Just enter whatever you want to print and drag it around to place it where you want it to go. The screen can also be accessed remotely via a web browser.

5. Easy to maintain maximum uptime

The G50i uses thermal inkjet technology, which is a cheap, maintenance-free printing method meaning plenty of uptime for your production line. Cartridge change is quick and simple, with no tools required.

Should anything need your attention, such as low ink, or another error, the status light on the top will change to orange or red. Alerts and statuses are easily accessible from one touch.

Are you’re ready to make the switch, or still not convinced? Either way, we’ll give you a free trial of the printer on your production line, so you can see for yourself whether it will work for you. Just get in touch with us!