Optimise Your Inkjet Printer

Why printing errors spell problems

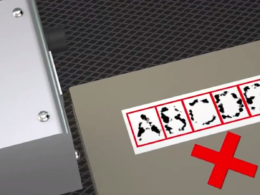

If you are coding your products or packaging, your print must be clear, easy to decipher and of uniform quality. Anything less can shake the faith your clients and/or customers have in your brand. If your codes are unintelligible, what’s the point of applying them?

Optimised printers allow you to maintain production efficiency. Yet without due care, printers can begin to cause problems: printing codes that are misaligned, difficult to read or completely illegible. That raises the potential for product recalls, rework, wastage and even legal action – all of which have associative costs.

The good news is that there are simple measures you can take – from procurement onwards – that will keep your printing equipment performing at optimum levels.

A variety of coding errors could end up on your products, ultimately affecting customer-facing brand packaging, as well as overall manufacturing efficiency and traceability

Installation

Ensure your product is installed by a technical engineer with the appropriate expertise – ideally, the manufacturer of your printer should offer full installation support and complete the necessary setup for you. That’s how we do things at PrintData.

Training

It sounds obvious, but sometimes the obvious is overlooked. The operators of your printers need to know precisely how to use them. That knowledge must extend beyond hitting go. Users should be aware of how to execute basic maintenance, schedule jobs, exchange consumables and detect developing problems before they cause disruption. With PrintData, full user training and onboarding is part of the service.

Good Housekeeping

Generally, printing errors are pretty straightforward to fix. That doesn’t stop them from being frustrating. Even the smallest errors can lower productivity, bringing entire lines to a complete halt and ultimately putting the brakes on efficiency.

How do you avoid these types of errors before they occur? Believe it or not, it’s the simple things. Like any other complex machine, following your housekeeping and cleaning program will help prevent errors in the long run. But stopping them altogether could be as easy as an annual optimisation routine.

Most coding errors are born from poor housekeeping. Now, halting your production line to perform routine cleaning on your printing equipment may appear disruptive. However, most coding technology requires regular cleaning (preferably daily) if it is to remain operating at its best. An inkjet printer should have the printhead cleaned at least once per day, and a jet alignment check at least once per week.

Your machinery user documentation should come with housekeeping instructions. By caring for your printing equipment, you will save time in the long run.

Optimisation

If you really want to reap the benefits of coding technology that’s working as seamlessly, effectively and efficiently as possible, an all-in approach is required. An annual optimisation routine will likely prevent printing errors altogether. That means checking things like ink temperature, pressure, modulation and ball fall time for viscosity. You need to make sure the cooling fan, positive air pump and solenoid valves are working properly. And you must review electrical supply, air supply – there are various items to check.

A number of items need to be replaced yearly, such as the ink filters, make-up filters and air filters. On Domino’s inkjet printers these are user-replaceable and don’t take long to do.

In order for your coding and packaging operations as profitable as possible, they have to be as efficient as possible. To remain profitable and efficient, they have to stay running. That’s where regular checks can come in. When you do regular optimisation checks (or get a PrintData engineer to do them) you have the peace of mind that comes with knowing your printing machinery investment is functioning at optimal performance and delivering the highest productivity possible. Day in, day out.

Want to know more about printer optimisation?

Reach peak performance by booking a free consultation with one of our engineers.